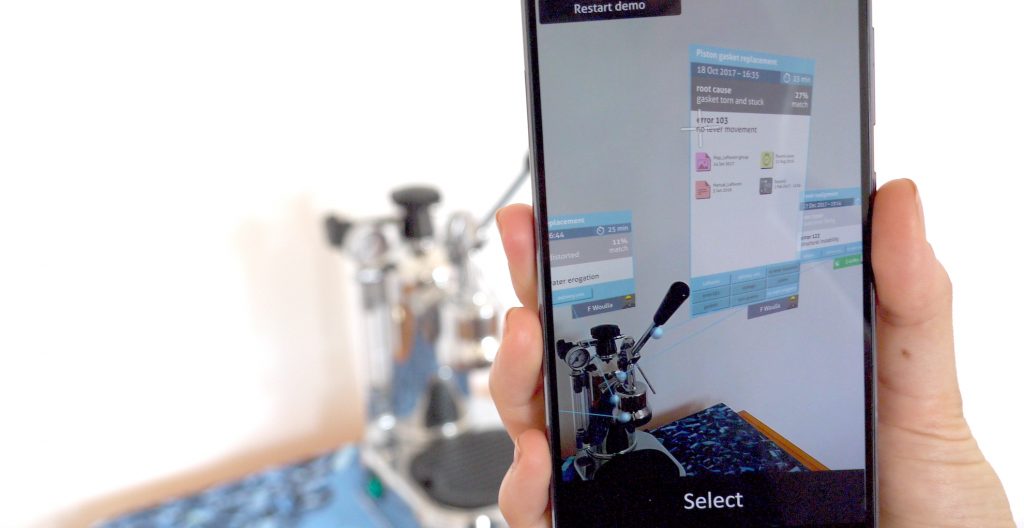

AR tools for industrial maintenance

AR tools for industrial maintenance Hitachi Share Experientia created digital AR tools that added intelligence and efficiency to the industrial maintenance and repair processes in the shopfloor’s context. A working hi-fi AR prototype was demonstrated to the C-suite. Based on the as-is maintenance process and existing pain points, Experientia conceptualized use-case scenarios, interaction flows and interfaces. 3 things to know Express delivery Our benchmark focused extensively on Europe, US, China and Japan while industry experts joined our research from 5 different countries, bringing insights from all around the world. Focus on core issues Through user journey mapping, main issues of industrial maintenance were uncovered and turned to key solutions for the interaction concept. Innovation throughout Cutting edge technology platforms like AR Core and Google’s Cloud Speech API were used to create a coherent system between mobile, smartwatch and earbuds. Gallery Multilayer tech ecosystem that combines three devices: smartphone, smartwatch and headphones Watch interface Watch interface Analysis diagram of the maintenance process and existing pain points In depth Service mix: Prototyping Information architecture Service design Behavioral modeling Context The client is an industrial player that has its own factories and also provides shop floor equipment to factories of their clients. In these environments any interruption in an assembly or production line is very costly. Challenge Efficient production time is lost due to misinformed, miscommunicated and non-standardized maintenance processes. The solution is a combination of user and system generated content that constantly improves according to daily incoming data about maintenance operations. The client would like to use AI and machine learning to provide values for all the stakeholders. Research Focused on worker’s needs to get jobs done rather than just spreading technologies, our solution was built on day-to-day tech providing maintainers with non-invasive support enabling them to be able to choose the best tech and device depending on the context and their personal experience. We used a (high end) coffee machine as a simulacrum of an industrial machine and mapped user journey and defined opportunities of digital tools for industrial maintenance. Design The proposed solution is a multilayer tech ecosystem that combines three devices: smartphone, smartwatch and headphones. They overlay timely, qualitative and statistical information to maintainers about assets, manuals and maintenance steps. The solution enables communication amongst colleagues and creates an easy reporting system, all integrated through a user and system generated database. Experientia designed a hi-fi prototype to showcase functionality and adequacy of an augmented multistep maintenance process on an exemplary machine. The prototype consists of an augmented reality app on mobile, an information app on a smartwatch and voice assistant interaction on a bluetooth headset. The demo across three devices proved interaction patterns and its benefits. The user journey consists of the six steps of a general maintenance process (asset failure, location, inspection, repair, spare parts, report and shift handover) organized along with macro phases (inspection, operation, communication, documentation). As second layer, we considered elements such as actors / tools and challenges and we highlighted the time consuming activities. Impact The client used the demo internally as a proof of concept to obtain further funding for future exploration As next steps the knowledge platform needs to be implemented and the solution should be tested on a shopfloor.. Related projects All Services Behavioral design Research and assessment Strategy B2B Collaboration UI, redesigning the filter navigation experience B2B Reinventing customer and supplier interactions for a multinational flooring company B2B Driving digital transformation one touch at a time Go back to our portfolio